Specify

Competitive Price Guarantee

Deliver

Fit

Fit

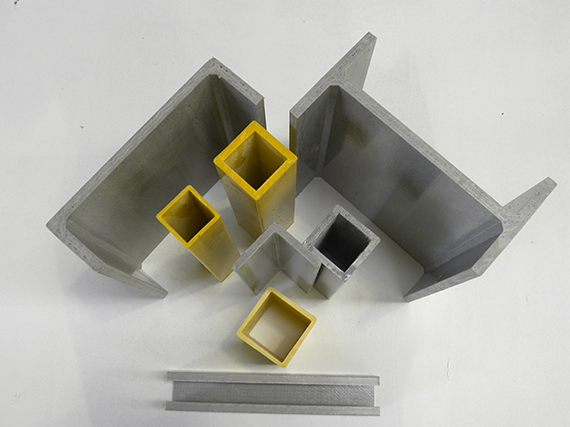

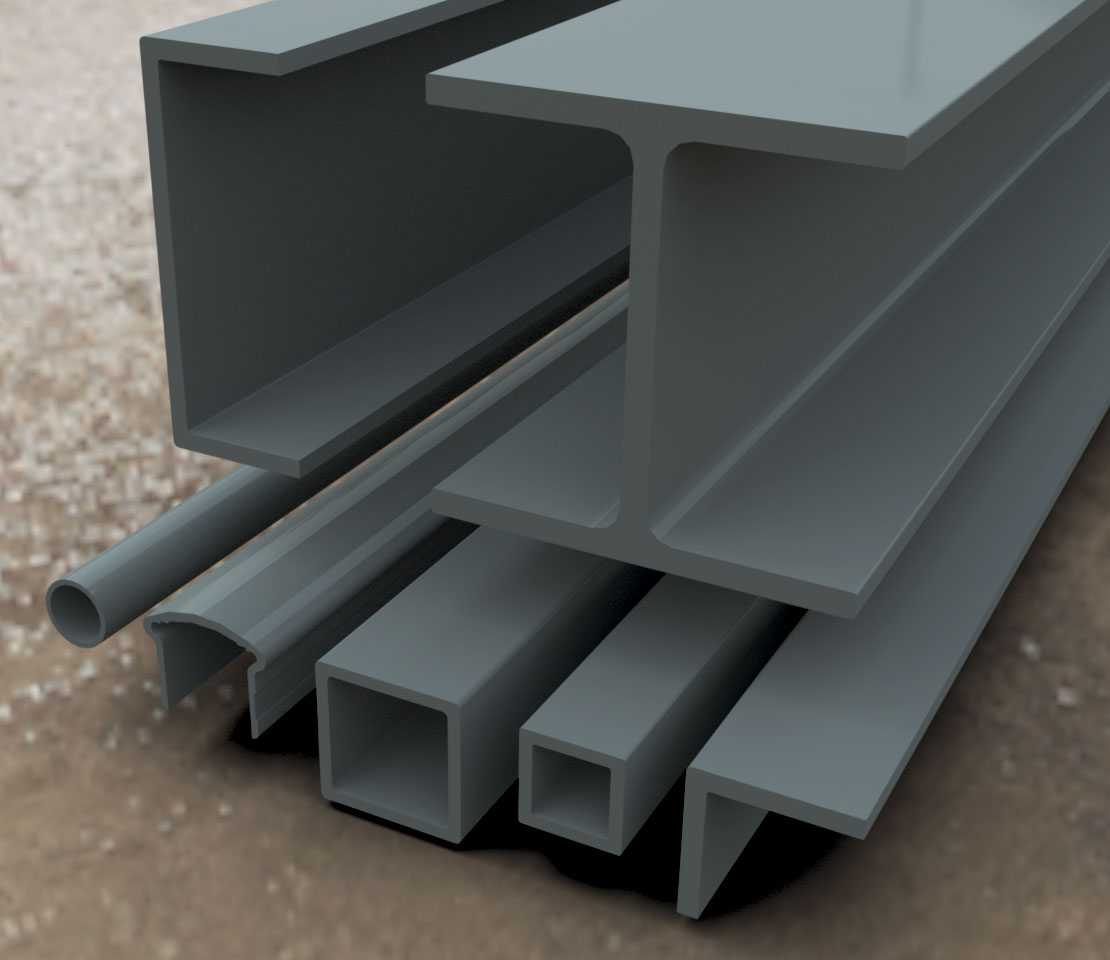

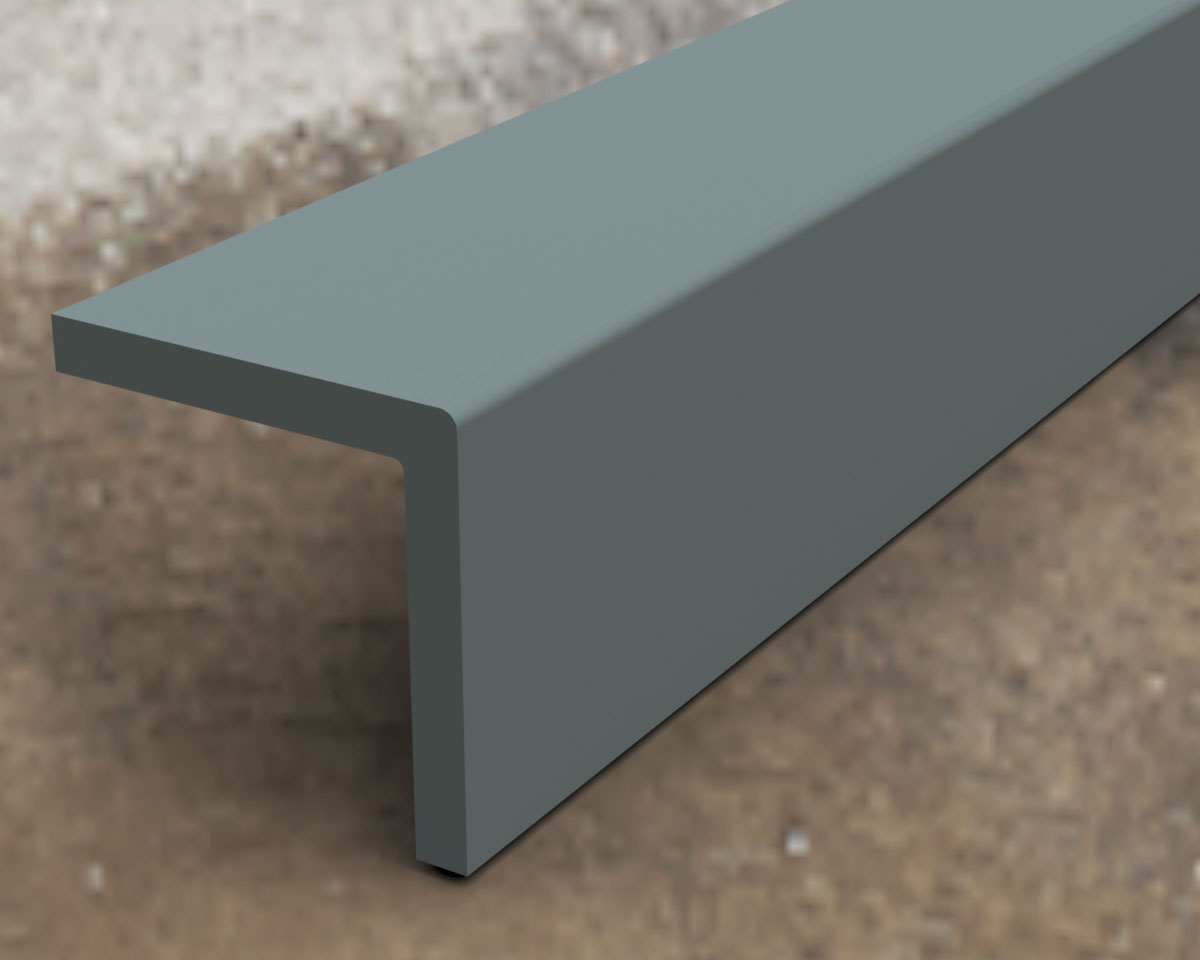

GRP PULTRUDED STRUCTURAL PROFILES

HIGH QUALITY PULTRUDED STRUCTURAL PROFILES

GripClad® GRP pultruded profiles are made from glass reinforced isophthalic polyester resin. This is reinforced with glass fibre and includes continuous strand mat and a polyester surface veil as the surface layer. This combination gives excellent corrosion resistance and long-life durability.

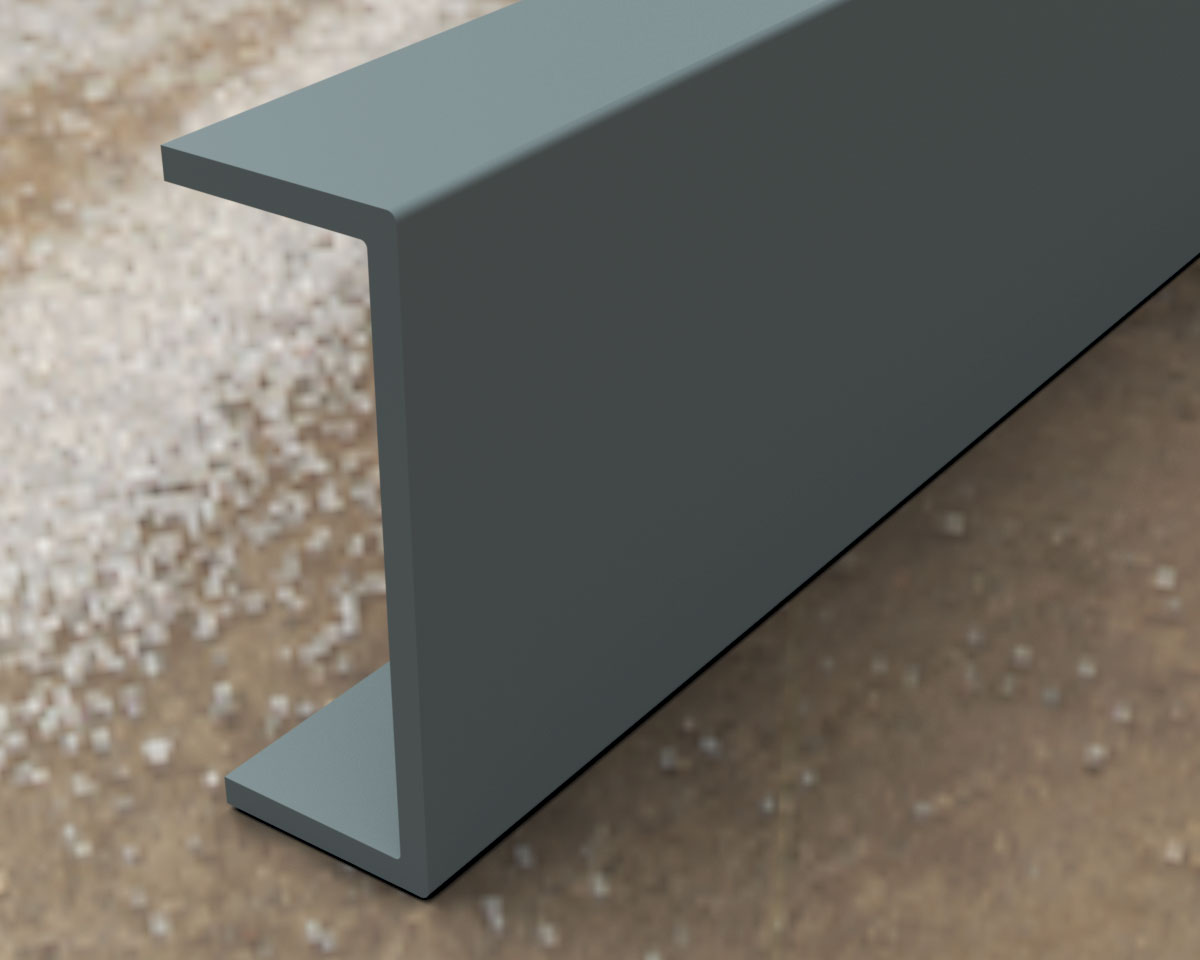

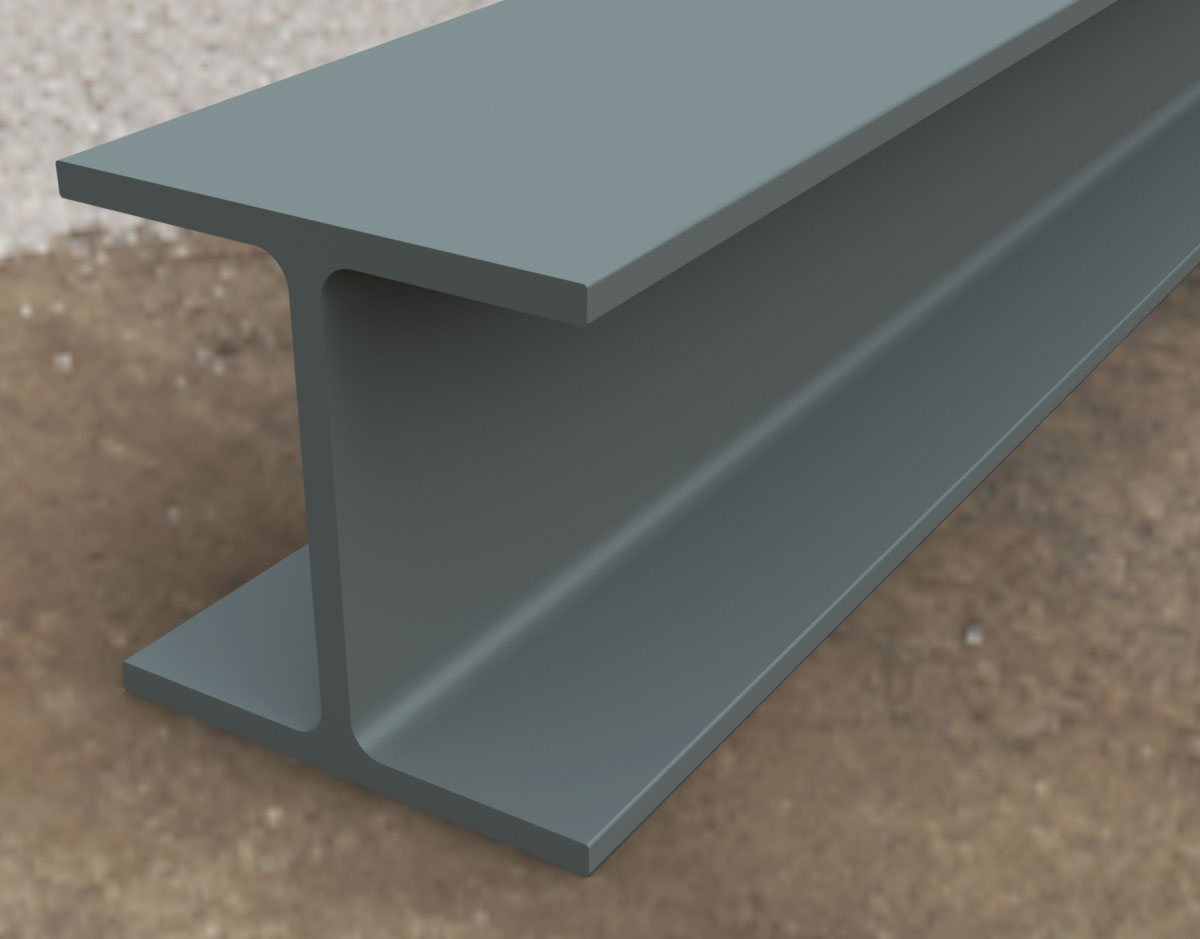

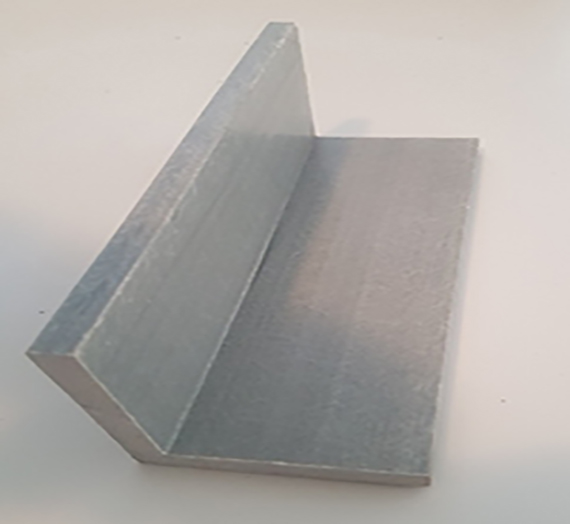

We supply a range of GRP Pultruded Profiles including Tube, I-Beam, WFB H-Beams, Channel, Box Section and GRP Angle Section to standard EN13706 E17 or E23, offering a wealth of construction opportunities.

GripClad Price Promise

Forget shopping around. Enjoy the most competitive costs around with our Price Promise.

Get in touch at enquiries@gripclad.co.uk or call us on 023 8040 6796

We supply a range of GRP Pultruded Profiles including Tube, I-Beam, WFB H-Beams, Channel, Box Section and GRP Angle Section to standard EN13706 E17 or E23, offering a wealth of construction opportunities.

Our GRP pultruded structural profiles fully comply with all the requirements of EN13706 -2 including dimensional tolerances and quality assurance parameters.

GripClad®’s structural properties meet the E17 for profiles with wall thickness of 5mm and below and E23 grade for profiles with wall thickness greater than 5mm of EN 13706 – 3 ISO 9001 registered quality-controlled production.

Key Benefits of GRP Pultruded Profiles

From an initial range of niche uses to industry-wide delivery, the potential for implementation is limited only by creative design and imagination.

Benefits include:

- Strong & Durable - Load tested for safety

- Corrosion Resistant - Virtually maintenance free

- High Impact Tolerance - Will not chip or crack

- Chemical Resistant - Suits most environments

- Low Electrical & Thermal Conductivity

- Lightweight - Reduced transport cost and lLoads

- High Fire Resistance

- Easy Handling Fabrication & Assembly

| Angle | U-Profiles | Boxes | I-BEAMS & Wide Flange |

|---|---|---|---|

| 25 x 25 x 3 | 50 x 30 x 4 | 25 x 25 x 3 | 120 x 70 x 8 |

| 35 x 35 x 5 | 76 x 25 x 4 x 6.35 | 38 x 38 x 3.2 | 150 x 80 x 10 |

| 50 x 50 x 3 | 76 x 35 x 5 | 38 x 38 x 5 | 152 x 76 x 6.35 |

| 50 x 50 x 5 | 100 x 50 x 6 | 44 x 44 x 6 | 200 x 100 x 9.5 |

| 51 x 51 x 6.35 | 150 x 50 x 6 | 5 1 x 51 x 3.2 | 200 x 200 x 10 = H Beam |

| 60 x 60 x 6 | 200 x 60 x 8 | 51 x 51 x 6.35 | |

| 75 x 75 x 10 | 200 x 60 x 9.5 | 102 x 51 x 3.2 x 6.35 | |

| 100 x 100 x 8 | 280 x 70 x 12 | 60 x 60 x 4.5 | |

| 76 x 76 x 6.35 | |||

| 101.6 x 101.6 x 6.35 |

All GripClad® Pultruded GRP profiles with a wall thickness of over 5mm thick meet the higher performance E23 grade. Those at 3-5mm wall meets the E17 grade.

| Pultruded Profile Property | Pultruded Profile Specification |

GripClad® GRP pultruded profiles are versatile and reliable, making them suitable in a variety of situations including:

- Service Risers

- Electrical Insulation

- Catwalks

- Work Platforms

- Bridge Decking

- Drainage

- Ramps

- Rainwater Harvesting Supports

- Sub Floors.

- Flooring Supports

- Steps

- Tank Supports

- Cooling Towers

- Racking Systems

- Pit Covers

- Pontoons

- Structural Flooring

- Marina Decking

- Duct Covers

- Trench Covers

- Stair Treads

Typical Industries

You'll find GRP pultruded profiles in a wide range of industries thanks to their durability and strength including:

- Chemical Plants

- Harbour

- Rail

- Power Stations

- Transportation

- Substations

- Local Authorities

- Oil Refining

- Pharmaceutical

- Food and Beverage

- Marine

- Water Treatment

- Shipyard

- Leisure

Structural profiles offer a unique combination of chemical resistance, size stability, high strength, thermal and electric non-conductivity.

The standard BS EN 13706 is the specification for Pultruded Profiles. This defines two grades of structural profiles.

Corrosion Resistance

GripClad® Pultruded GRP profiles are able resist, without depletion, any exposure to constant splash, spills, fumes and gases and will demonstrate superior quality over other materials.

Fire Resistance

Meets Class 1 Flame Spread rating of 25 or less, in accordance with ASTM E-84 Tunnel Test Method. If a flame spread requirement of less than 25 is needed, we can supply this bespoke.

HOW WE WORK

We’re more than just a specialist supplier of GRP and anti-slip solutions, we help our customers through the whole process.

From helping you decide what you really need, to custom shaping and fitting the product, we’re here to support.

01 Specify

We’ll work with you to make sure you’ve got exactly the right product for your application, saving money on wasted material.

02 GripClad Price Guarantee

We monitor the market to ensure that we’re offering the most competitive costs, so you don’t have to worry about shopping around.

03 Deliver

Swift delivery available to the United Kingdom and Europe. Or we’ll nominate a professional installer if required.

04 Fit

As part of our complete service, we can nominate a professional installer if required.

GRIPCLAD® IS PROUD TO WORK WITH SOME GREAT BUSINESSES

Why choose grp pultruded profiles?

Applications for GRP Pultruded products are rapidly evolving. Reduced mass, corrosion resistance and superior weight-strength ratios offer significant benefits in the built environment. From an initial range of niche uses to industry-wide delivery, the potential for implementation is limited only by creative design and imagination.

Structural profiles offer a unique combination of chemical resistance, size stability, high strength, thermal and electric non-conductivity. Each composite structure is available in a number of dimensions. This is to suit a variety of applications and design needs.

Major asset-owners are fostering innovation and steadily increasing the use of GripClad® GRP Pultruded Profiles in both reinforcement and new build projects. Just call us and we will be pleased to help.

Minimum properties that are required for each pultruded profile grade

| Property | Unit | Test Method | Minimum Properties | ||

|---|---|---|---|---|---|

| E23 Grade | E17 Grade | ||||

| 1.1 | Full section test | GPa | Annex D, EN 13706-2 | 23 | 17 |

| 1.2 | Tension modulus-axial | GPa | EN ISO 527-4 | 23 | 17 |

| 1.3 | Tension modulus-transverse | GPa | EN ISO 527-4 | 7 | 5 |

| 1.4 | Tension strength-axial | MPa | EN ISO 527-4 | 240 | 170 |

| 1.5 | Tension strength-transverse | MPa | EN ISO 527-4 | 50 | 30 |

| 1.6 | Pin-bearing strength-axial | MPa | Annex E, EN 13706-2 | 150 | 90 |

| 1.7 | Pin-bearing strength-transverse | MPa | Annex E, EN 13706-2 | 70 | 50 |

| 1.8 | Flexural strength – axial | MPa | EN ISO 14125 | 240 | 170 |

| 1.9 | Flexural strength – transverse | MPa | EN ISO 14125 | 100 | 70 |

| 1.10 | Interlaminar shear strength-axial | MPa | EN ISO 14130 | 25 | 15 |

Get in touch with us today

Get in touch at enquiries@gripclad.co.uk or call us on 023 8040 6796

Why Choose GRIPCLAD®

Made-to-measure products

Order our product in standard sizes or we’ll cut precisely to your application.

Plain-speaking, no-nonsense support

Honest, down-the-line advice and straightforward service to save you time and hassle.

Competitive pricing

Benefit from superior quality products at a cost you won’t beat.

Barry Eagle – Founder and CEO of GripClad®

Barry is the founder and CEO of GripClad® and is widely experienced in the GRP composite and anti-slip industry. He has built many great relationships over his 20 years at GripClad® and is always on hand to speak to customers, both present and future. His wealth of experience means he can guide you on the products you’ll need, as well as advising you on whether an alternative may be better.

or call us on 023 8040 6796