GRP (Glass Reinforced Plastic) is an excellent alternative to steel. The many properties of GRP mean that, when compared to steel, GRP alternatives are the most sensible decision in a scenario where steel was previously thought to be the best choice.

Steel is renowned for being extremely strong and is often used because of its durability and adaptability. GRP can be moulded to a variety of shapes and is used for a range of useful and adaptable products. Despite the many qualities that steel has, GRP often outperforms when it comes to all round use, especially when used as grating.

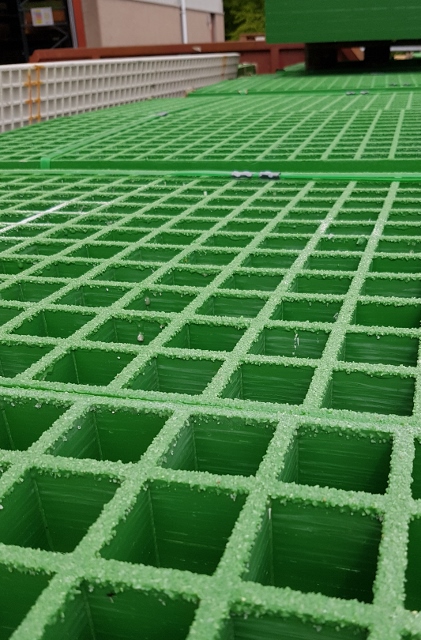

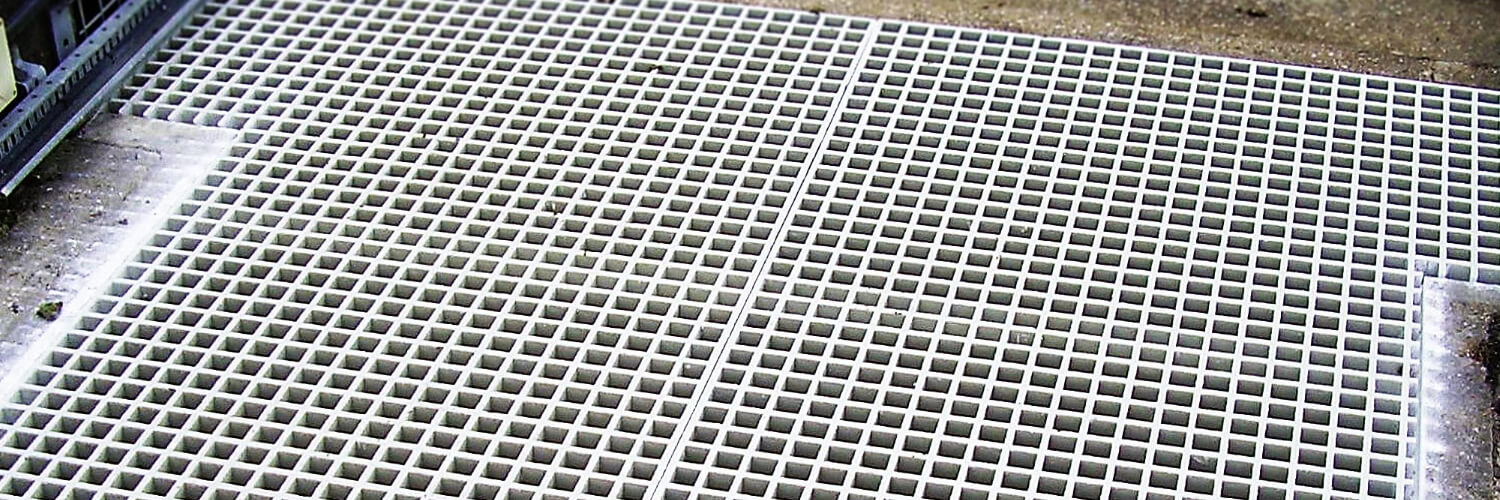

GRP Grating vs Steel Grating

In environments where steel would be used underfoot, such as in marinas, public access points and more, GRP grating is a safer and more durable alternative.

Gratings are often used in high traffic environments, or areas where safety is a high priority. It’s important that the most durable, corrosion-free and anti-slip material is used, not only to create a safe working environment, but to reduce risks to both staff and visitors. Here, GRP is the best alternative to steel, as it is both lightweight, slip-resistant and doesn’t corrode under bad weather or exposure to water.

Properties of GRP

| GRP Grating | Steel/Aluminium Grating | |

| Lightweight | ✔ | ❌ |

| Easy to Transport | ✔ | ❌ |

| Easy Installation | ✔ | ❌ |

| Maintenance-Free | ✔ | ❌ |

| Use Hand Tools to Cut and Shape | ✔ | ❌ |

| Zero Scrap Value | ✔ | ❌ |

| Any RAL Colour | ✔ | ❌ |

| Slip Resistant | ✔ | ❌ |

| Corrosion Resistant | ✔ | ❌ |

GRP vs Steel Properties

Strength of GRP vs Steel

When put to the test, the strength of GRP comes into its own. Usually, GRP is used in situations where there is always footfall, or where footways must have a high weight to strength ratio.

As an example: If you use a 25mm, 1-metre-wide grating that is supported on 4 sides, it will easily withstand 1/3 ton per square metre., while a 38mm grating can reach 1⁄2 ton per square metre.

The performance improves when the width of the area is reduced. At 300mm wide, the 38mm grating can withstand loads in excess of 12 tons.

Lightweight Properties of GRP vs Steel

Steel gratings are heavy, difficult to assemble and can’t always be used in some situations because of the supports needed. GRP gratings make a great alternative because they are one third the weight of steel. This makes GRP easier to transport and install into any desired area.

Anti-Slip Properties of GRP vs Steel

In situations where there is excessive water exposure or consistent bad weather, GRP is a far better solution than steel. Not only can steel corrode quicker, when wet, steel becomes slippery underfoot, which can easily lead to slips and trips.

With GRP, there are no such worries. Made with an aluminium oxide grit on top, GRP gratings are designed with high anti-slip properties early on. GRP products by GripClad are known for exceptional slip resistance and have been awarded an “excellent” pass in tests carried out to BS 7976-2:2002.

Corrosion Resistance and Non-Conductive Nature of GRP vs Steel

As a result of the variety of resins used in GRP gratings, they offer a high resistance to corrosive substances that are used in a wide variety of applications. If you're unsure whether our GRP products will hold up better than your steel gratings, we can carry out tests to ensure they are resistant to all potential chemicals at use in or around your area, and are able to tailor the resin and fibreglass blend to ensure the exact properties.

And, while steel is a conductor of electricity, it can still conduct some form of electricity. GRP, as it’s made from two materials that don’t conduct electricity, is safe for use, even amongst high voltage equipment.

RAL Colours and Consistent Pigmentation of GRP vs Steel

Unlike steel, where specific colour requirements mean that the steel must either be treated or powder coated, no such treatments are required for GRP. A process of constant mixing of pigmentation and resin ensures a moulded-in colour. Standard stock colours are green, grey and yellow, and bespoke RAL colours are available on request.

Installation and Maintenance of GRP vs Steel

GRP gratings require next to no maintenance and are extremely durable, resisting weather conditions, heavy footfall and traffic usage and chemicals. Plus, GRP also has no scrap metal value, making it ideal if you have had any previous bad experience with metal being stolen.

Installing, as GRP is lightweight and easy to manoeuvre, is also simple, and won’t take up more time than necessary. Another good part of GRP over steel when it comes to installation is the ability to make minor onsite changes without the need for welding. You can make changes to the size and cut of panels easily with GRP.

Why is GRP Better Than Steel?

Given the extensive list of GRP properties, it is apparent why this material is growing in use as an alternative to steel gratings. GRP not only excels but also demonstrates itself as a superior material altogether. It is affordable, easy to install and maintain, and lasts in all conditions.

If you are interested in any GRP products, please make sure you have the following information to hand when you contact us:

- A list of all chemicals that the product will be exposed to

- Minimum, normal and maximum operating temperatures

- Duration of operating temperatures

- pH range

- Normal operating concentrations of chemicals including trace amounts